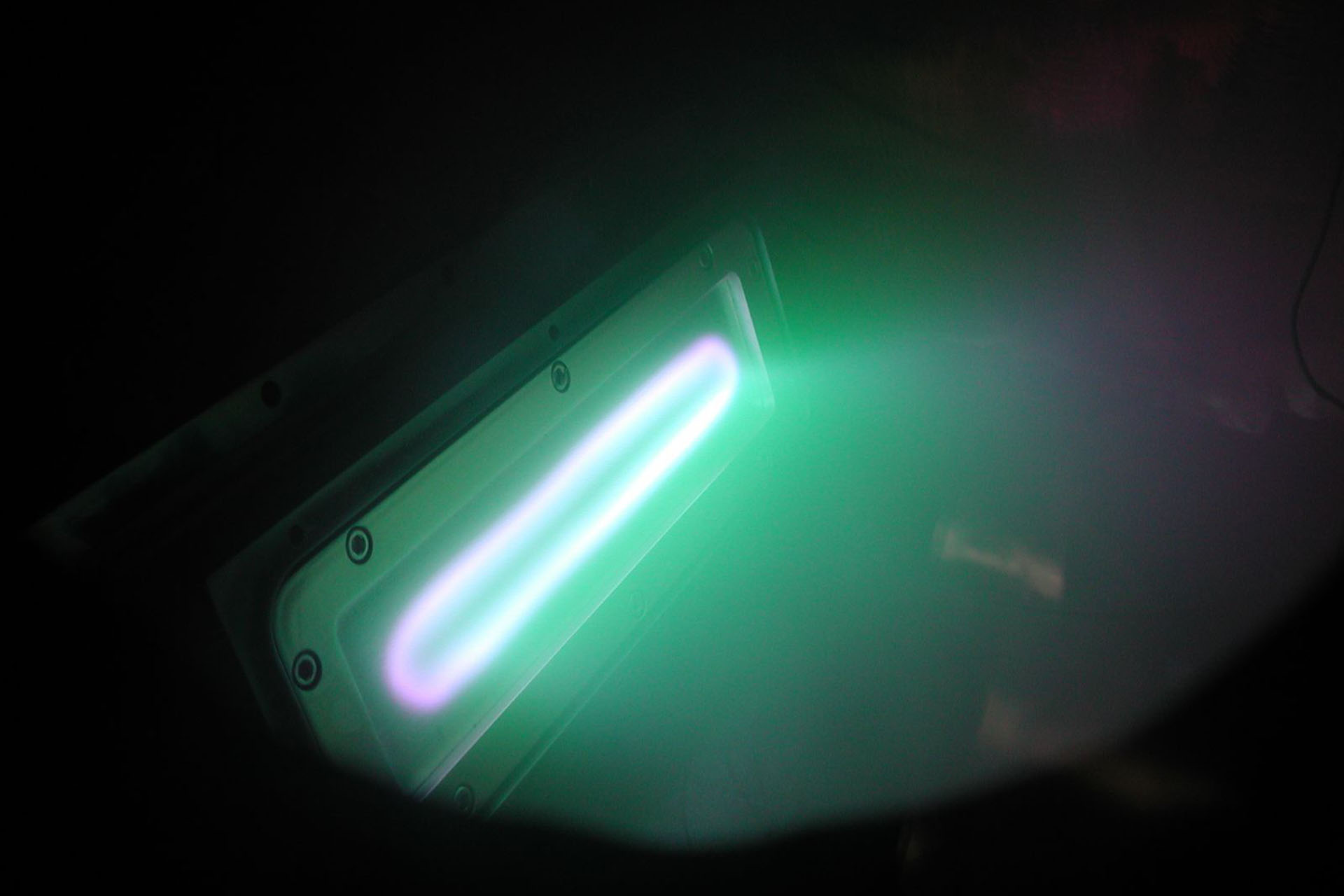

UV led lamps represent the current benchmark for energy efficiency in radiation curing. Our new formula adapts the well known UV products of our range to the emission spectrum of the new lamps. The result is a coating with high cross-linking and superior performance even if cured with the new LED lamps.